Meet The Guild | designers, makers, craftsmen, and fabricators

We had the good fortune of connecting with The Guild and we’ve shared our conversation below.

Hi The Guild, what is the most important factor behind your success?

Our passion for manifesting design in the physical realm comes from the undergraduate architecture program at The University of Buffalo. The exploration of the unknown and undefined comes from the graduate program at SCI-Arc. Although we experienced it at different times, the commonality of “nothing is impossible” is what built the working relationship. Over the years we’ve been through the growing pains of having our own business, getting acquired, developing new products, and leading a large group of people as well as teaching. There is nothing more enjoyable than being surrounded by people who are passionate about what they do, diverse in what they offer, and always interested in new ideas. We think that is a perfect summary of the current Guild team consisting of Evan Emery, Mikhail Gladchenko, Jason Vetsch, Casey Fowler, and Jesus Carrillo.

We are still in the early days of brand building, so it’s hard to say if we are 100% successful just yet. But we believe if we focus on the 4 main principles, success will be a byproduct of those actions.

1 – Building a team

We believe that the foundation for a perfect outcome starts with the team. Building the right team and building up every individual within that team is our number one priority. When we look to assemble a robust team, we look for the diversity of skillsets. That diversity allows us to come together and overcome daily challenges at a faster rate while continually learning from one another. We also believe partnering with industry leaders to leverage their skills sets helps to expand ours.

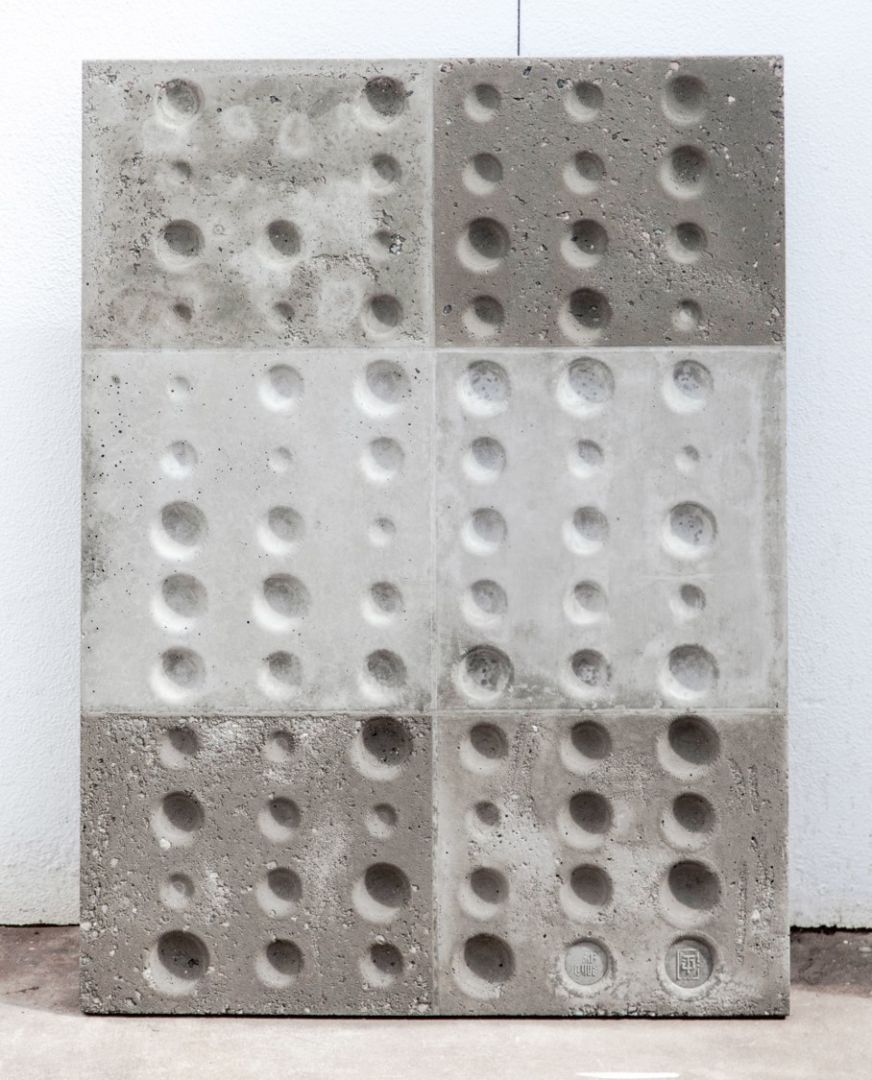

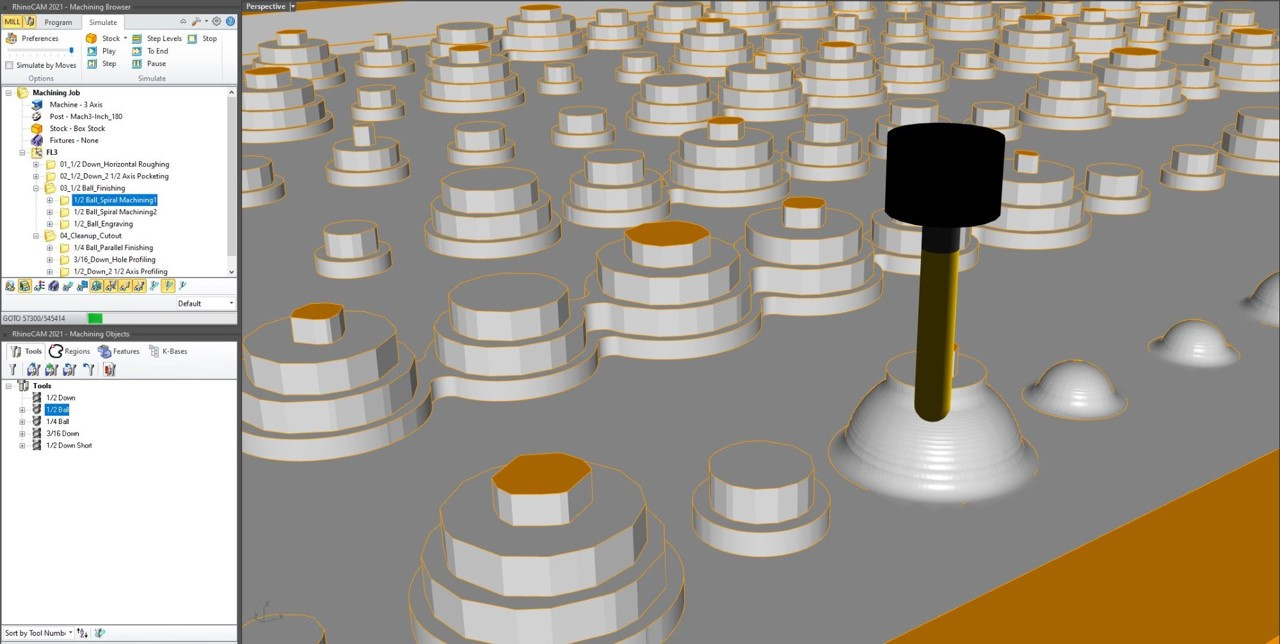

2– Experiment: Fail: Push Boundaries

As much as it’s very cliché to say “think outside the box” the truth is as simple as that. With a diverse set of projects every year, we are constantly researching, learning, implementing, and expanding our tools, production/manufacturing processes, and utilizing materials in new ways. Allowing an experimentation platform for prototyping and embracing failures has a tremendous amount of value more so than getting it right on the first time. Those failures allow room for innovation and in some cases reframe how one looks/approaches the problem altogether. In our R & D process, we think all systems and methods should be explored as a possibility while never accepting the status quo.

3– Dedication to craft

Everyone is capable of putting two pieces of material together. At its core, building something new is as simple as that. The craft then becomes the quest to perfect that connection. By virtue of continuously working on something different week to week, we work hard at refining the craft while seeking perfection. We take a lot of pride in what we do, and how we do it. We don’t like to draw the distinctions between an element being front and center or something that is hidden inside the walls. We rely heavily on our craft to bring the original design intent to life. Sometimes the hard way is the right way, never shy away from complexity if it solves the problem at hand.

4 – Stay organized and optimize

We don’t work in a typical production setting, making the same or similar items daily, where you can keep refining the product and the production process over several iterations. Everything we do is unique from project to project and most often is a response to site conditions. This creates a steep learning curve on some projects as well as a level of difficulty on the production optimization end. We are always trying to take a manufacturing approach to everything we do. We look at various well-established industries for queues organizing the daily chaos. Traditional manufacturing has the term “just in time”, meaning that the items you need to finish a task arrive at the exact time you need them, which helps eliminate unnecessary labor. Chefs around the world have the term “mise en place”, meaning “putting in place”, everything is prepared and is in the right place before the service starts. That allows them to stay highly agile from 1 minute to the next. In the first scenario, the system is slow to adapt, in the other, the system is designed around minute-by-minute changes. As a small shop, in staffing and physical size, we are always looking for ways to strike a perfect balance on how we organize the space, how we utilize fixturing to increase quality and production time, and how much production we can do in the shop where all the tools are at our disposal and how much is done on site. It is also important that we reevaluate both digital and physical workflow on a regular basis to maintain constant improvement to the process. Embracing change is needed to stay on the cutting edge.

What should our readers know about your business?

We are less concerned about defining what sets us apart and are mostly focused on what and how we improve every day. We don’t view companies who work in the same field as competitors, we view them as collaborators, and we lean on each other throughout the years. We have a big and exciting vision for what The Guild could be in the near future, and we are determined and focused on trying to take steps toward that future. Ultimately, we’ll let time, clients and body of work define how and why we are so different.

How did you get to where you are today business-wise. Was it easy? If not, how did you overcome the challenges?

Having a custom fabrication shop is always a very challenging business to be in. There is no manual for what we do, there are not too many people to turn to for answers. By encouraging collaboration and investing in our team, we rely on the diversity of the team to get us through challenging tasks.

We are extremely lucky to have clients who understand, appreciate, and encourage our obsession with perfection and flawless execution. There are projects that run longer than expected, we try to do our best and identify that early on and find ways to adjust the processes and regain efficiency. We want every project to be better than the last and trying to cut corners is just not something we are interested in doing. We try to learn as much as we can from our failures and quickly tweak and improve our process in the event we encounter similar conditions in the future. Last, active collaboration and full transparency allow us to have clients that trust us to bring their vision to life.

What are the lessons you’ve learned along the way. What do you want the world to know about you or your brand and story?

Don’t sell the client on everything you can do. Help them solve the problem of today.

Our background is very diverse in what we can do and offer.

The list of lessons we’ve learned through the years is endless, and I hope we continue to learn, it means we are asking new questions.

If you had a friend visiting you, what are some of the local spots you’d want to take them around to?

Let’s say your best friend was visiting the area and you wanted to show them the best time ever. Where would you take them? Give us a little itinerary – say it was a week long trip, where would you eat, drink, visit, hang out, etc. In your view what are some of the most fun, interesting, exciting people, places or things to check out?

Places to see

Taliesin west

Burton Barr Central Library

NAU–Phoenix Biomedical Campus

Desert Botanical Garden

ASU Campus

Food and drinks and entertainment

Pomeroy’s

The Vig Fillmore

Taqueria La Hacienda on buckeye and 3rd street

Rose and crown

Stardust Pinbar

Midtown and Melrose district, as it has a diversity of gastropubs with interesting interiors.

Website: https://www.bytheguild.com

Instagram: https://www.instagram.com/bytheguild

Facebook: https://www.facebook.com/byTheGuild